Toll Manufacturing & Contract R&D

From lab-scale samples to tanker truck quantities, we work with you every step of the way.

Featured Projects

View All Projects

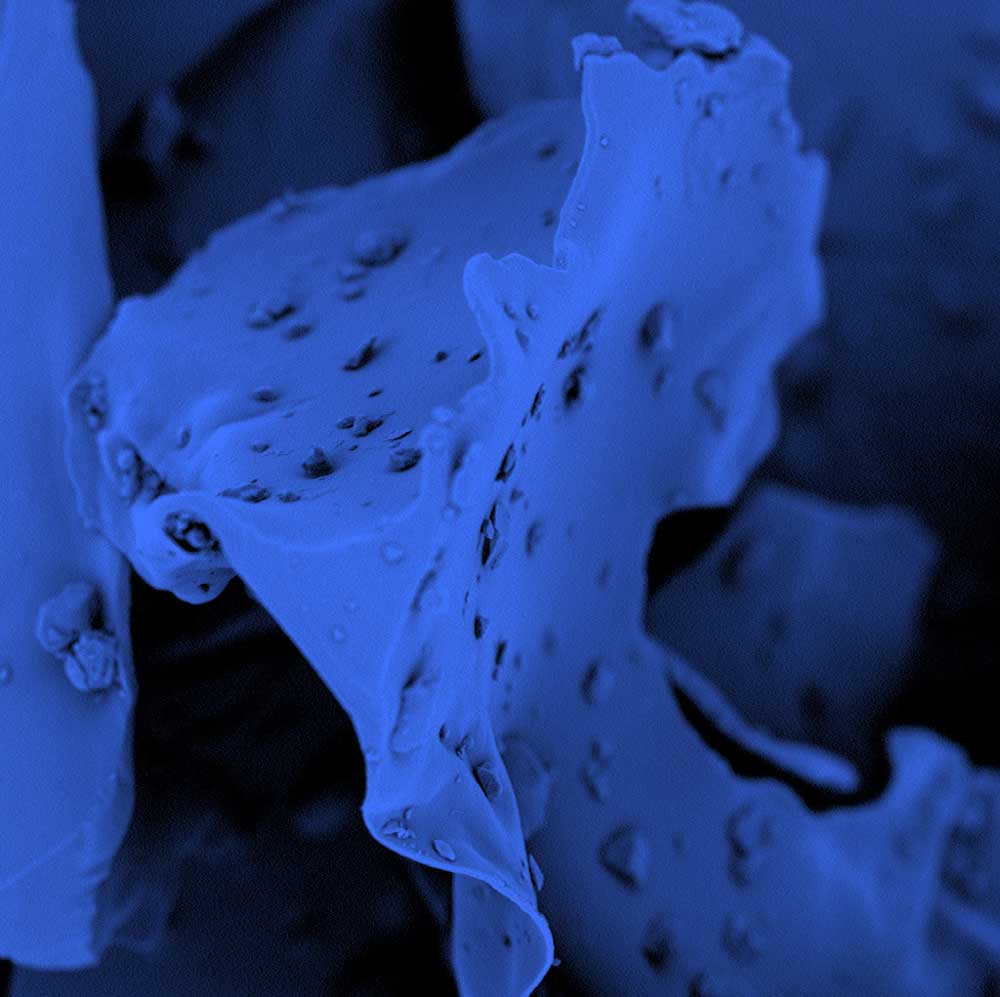

MAIC to Surface Modify Particles & Increase Flowability

MAIC to Surface Modify Particles & Increase Flowability

The Challenge: AVEKA's technical team was asked to change the flow properties of a particle. Fumed silica is typically added to a material in order to make the material flow...

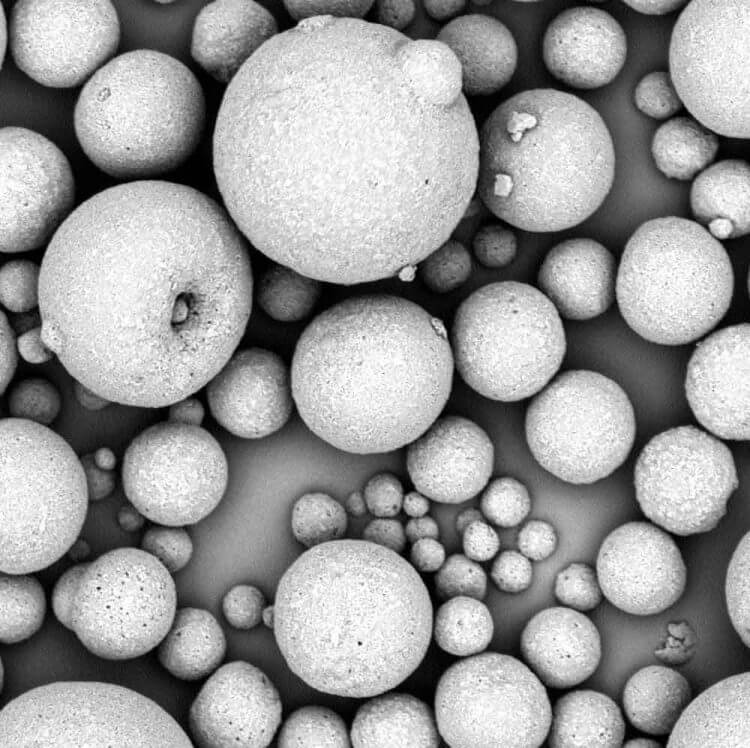

Spray Drying Highly-Engineered Particles

Spray Drying Highly-Engineered Particles

The Challenge: The customer was looking for a way to create ceramic particles for a specialty application. Particle morphology was important: particles could not be hollow, broken or irregularly shaped....

Ball Milling for Size Reduction of High Purity Materials

Ball Milling for Size Reduction of High Purity Materials

The Challenge: The customer was looking for a way to reduce the particle size of their specialty value-added ceramic pigment. While size reduction is a common request, in this case...